Owen-Illinois RibbonTM Glass Forming Technology

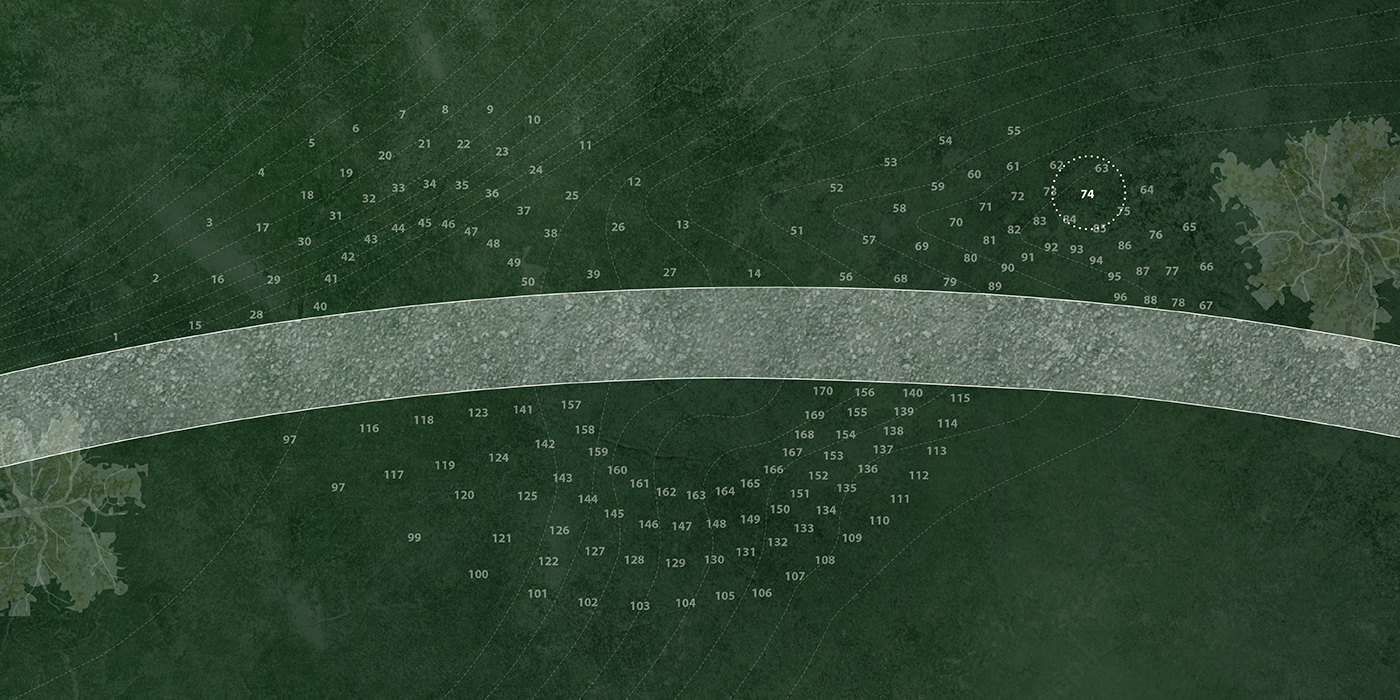

Location 74

Owner: Tom and Betsy Brady

This very interesting looking glass-plastic bottle was made by Owens-Illinois around 1970 using a newly developed and patented glass forming process that O-I called RibbonTM technology. The RibbonTM technology worked in a similar way to the forming process that is used to make glass light bulbs. The glass container itself was formed by blowing a section of the ribbon into a container-shaped mold with a spherical base, a necessary design feature that would maximize the pressure resistance strength of the ultrathin glass. The resulting glass container was then placed in a flat-bottom preprinted plastic base cup in order to assure shelf stability and to provide impact protection for the spherical-bottom glass container. While the forming process was developed well enough to become commercial, the biggest challenge O-I found was creating a functional finish (wide mouth opening) and a closure system that could be easily applied and which would seal the container properly. O-I also found that the dimensions of the blown wide mouth finish were difficult to control. The final multi-component package can be visualized by imagining a glass light bulb with a wide mouth at the socket end of the bulb and which utilized a "rip cap" as a closure. Even after much experimental work, however, O-I concluded that sealing reliability was just not sufficient. While this very novel RibbonTM glass forming project was never commercialized, it evolved further to eventually become O-l's very successful PlastishieldTM process which involved shrinking a polystyrene foam full length body sleeve onto a glass bottle which served two purposes; the sleeve served as a preprinted label but also limited the spread of glass shards if the bottle was ever dropped and broken. PlastishieldTM glass containers were designed to maximize strength while allowing a slight reduction in the glass weight. Impact performance was also increased by wrapping the contact points and bearing surface with the preprinted foamed polystyrene sleeve.