World's First Plastic Tennis Ball Can

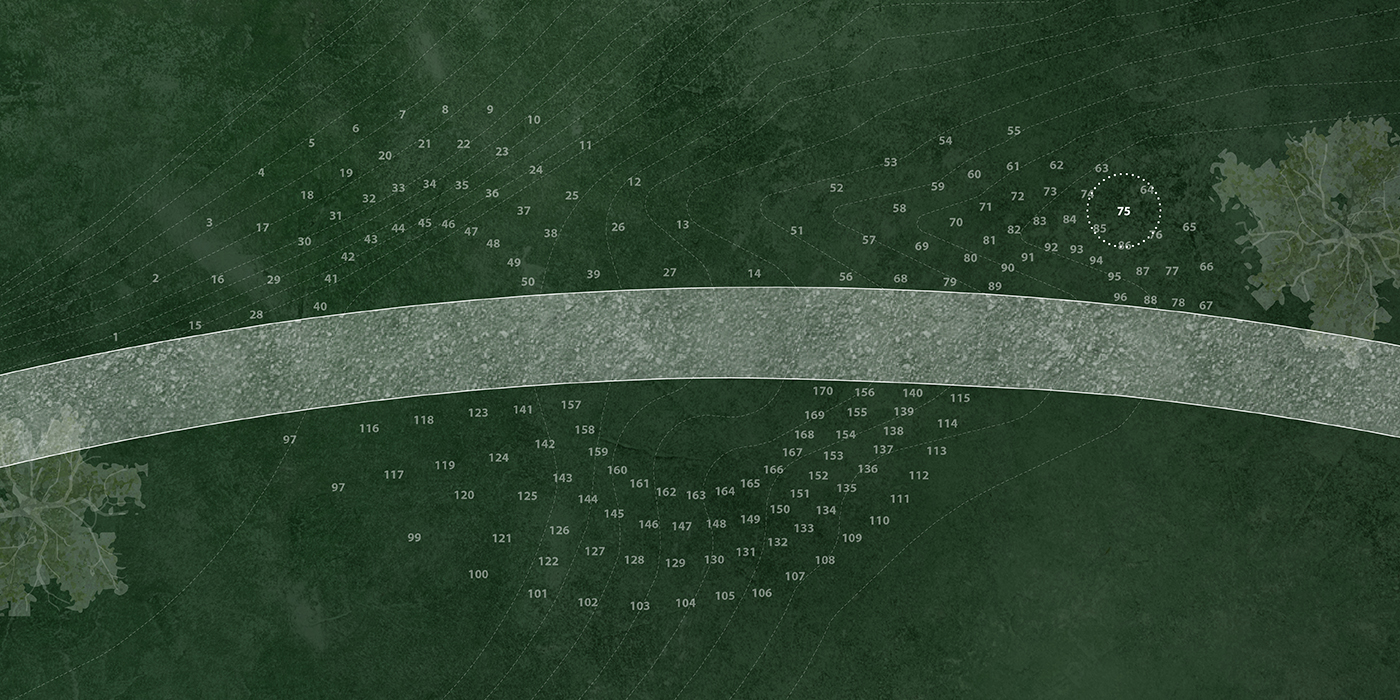

Location 75

Owner: Tom and Betsy Brady

Before 1925, tennis balls were packaged in wrapped paper and paperboard boxes. In 1925, Wilson-Western Sporting Goods Company introduced cardboard tubes and in 1926 the Pennsylvania Rubber Company released a hermetically sealed pressurized metal tube that held three balls with a church key to open the top, which became the standard package for tennis balls until the plastic tennis ball can was developed. Metal cans remained the only tennis ball can option up until 1984 when Wilson approached Owens-Illinois (O-I) and asked O-I whether a pressurized plastic tennis ball can was possible. However, O-I was beginning to question their continuing involvement in the plastic PET bottle business which was competing (too) successfully with O-l's historic glass bottle business, so O-l declined to pursue the plastic tennis ball can development with Wilson. Wilson then approached O-l's biggest PET bottle competitor, Continental PET Technologies (CPET), headquartered in Amherst, NH, and it was CPET that then developed the very first commercial PET plastic tennis ball can which they successfully commercialized over the next several years. An interesting and little-known connection with Toledo and Northwest Ohio is, however, that because O-I had decided not to pursue its PET bottle manufacturing business, O-I VP and Technical Director, Dr. Tom Brady, left O-I about that same time to create Plastic Technologies, Inc. (PTI). Because Tom and PTI were contracted to become the Coca-Cola Company's PET technology development partner, and because Coca-Cola had just licensed CPET's PET bottle technology, Tom also ended up working closely with CPET to assist in the development and commercialization of the now ubiquitous plastic tennis ball can. While the plastic tennis ball can might be viewed as just another can design similar to the metal can design, in fact, it was necessarily a far more complex design in plastic, and the plastic tennis ball can was only successful because it incorporated several innovative and artistic design features, including the roll-top metal opening feature which required a unique plastic-to-metal sealing technology, also invented and patented by CPET, and a unique and patented pressure-resistant bottom design called the "Suppa Base" which was named after CPET inventor and employee, Suppayam Krishnakumar.